Enterprise Asset Management (EAM)

Maintenance & Monitoring in Industry 4.0

New potentials through innovative technologies

Maintenance solutions for complex plants

The greatest challenge for maintenance managers is to map complex processes of technology and adjacent areas (materials management, purchasing) in a single central system in a user-friendly way. The goal is to keep existing plant structures operational in their entirety or to further optimize them.

For this purpose, all plant components must be recorded in a specific hierarchy or local assignment. Subsequently, it is necessary to record all standard maintenance as well as the current conditions of the plants. With a maintenance strategy based on this, maintenance planning can now be created.

Above a certain plant size, this enormously data-intensive process can no longer be solved with decentralized tools, especially since additional requirements such as verifiable inspections, environmental regulations, etc. must be guaranteed.

Enterprise Asset Management software has been developed for such challenges and can support the most extensive and complex challenges in this area.

1

Maintenance & Monitoring in Industry 4.0

2

Advantages of Enterprise Asset Management

3

Enterprise Asset Management Strategy Circle

4

RODIAS Expert Tip: Solutions and Partners

1

Maintenance & Monitoring in Industry 4.0

2

Advantages of Enterprise Asset Management

3

Enterprise Asset Management Strategy Circle

4

RODIAS Expert Tip: Solutions and Partners

Build on the EAM expertise of RODIAS

Based on almost 40 years of experience in software development and consulting for KRITIS customers (critical infrastructures such as power generation and chemical industry) in the areas of maintenance and EAM software and processes, we know our customers’ needs very well: We can offer you a product that includes the specific process and functional requirements of your target customer segment for your business in different industries.

By combining our in-depth technical knowledge and process expertise, we also provide our customers with outstanding customer service and offer the best and most comprehensive enterprise asset management solution: EAM MX-Plus, a software solution optimized for managing complex assets.

Briefly explained: How you can increase productivity and reduce operating costs with EAM.

By loading the video, you agree to YouTube`s privacy policy.

Learn more

Maintenance & Monitoring in Industry 4.0

An enterprise asset management (EAM) system involves managing the maintenance of all of an organization’s physical assets throughout their lifecycle. EAM systems include the planning, optimization, execution and tracking of the required maintenance and servicing activities of the assets. In the EAM system, the assets are described in detail in a structured manner with the associated spare parts, materials and tools.

The priorities, resources, qualifications, certificates and other relevant information for organizing the maintenance work are kept in the EAM system. The operations and deadlines are planned in coordination with production, the work assignments are supported with relevant data and information and logged after execution with mobile EAM solutions.

In terms of holistic asset lifecycle management, the use of an EAM system begins with the planning of a plant. Construction and any problems that arise are already documented in the system. Commissioning with the first incidents is logged. During operation, the EAM system supports maintenance. And during decommissioning, it provides the data required for dismantling to ensure sustainable disposal of the plant. For us, EAM data is the basis of a digital twin. From the beginning to the end.

Advantages of Enterprise Asset Management

One system allows a complete overview of all plants

This includes, for example, the automated ordering of spare parts or the consideration of whether a critical maintenance interval might be exceeded with the planned productions.

By connecting with ERP, MES and other systems, EAM enables more advanced tasks and automated workflows

Once implemented, all work and processes, as well as statuses around the assets, are planned and recorded in a central software. The hierarchical or location-based structure of the assets allows you to view related assets at a glance and release them for maintenance, for example.

Mit langjähriger Erfahrung im Kundenservice und in der IT-Administration unterstützen wir Sie in den Bereichen Kundensupport, Softwareentwicklung, Projekt- und Servicemanagement bis hin zu Datenbanksystemen und IT-Sicherheit.

Increased plant availability and resilience

With connectivity to IoT systems, possibly in conjunction with AI systems, EAM can automatically generate inspection or maintenance orders, protecting you from unplanned downtime.

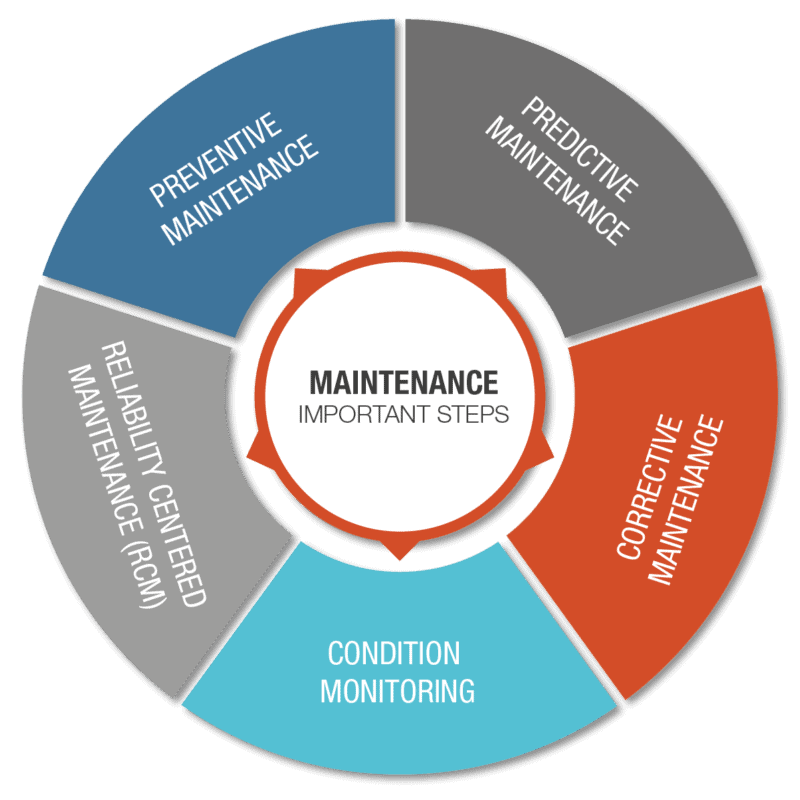

Enterprise Asset Management Strategy Circle

- Enterprise Asset Management (EAM) encompasses the management and control of physical assets.

- EAM systems automate and optimize the maintenance, repair and spare parts delivery of assets.

- Predictive Maintenance, Preventive Maintenance, Prescriptive Maintenance and Corrective Maintenance are the core of EAM.

- Condition monitoring is used to continuously monitor the condition of assets. In this way, failures are detected immediately and risks of failure are identified at an early stage.

- Reliability Centered Maintenance is an EAM strategy. It aims to extend the life of assets and minimize unplanned downtime.

- The use of enterprise asset management (EAM) software leads to more effective and efficient operations, a reduction in downtime, and an increase in asset performance, life, and reliability.

Preventive Maintenance

Preventive maintenance is a strategy for avoiding unplanned machine downtime. Regular inspections and maintenance work ensure compliance with legal or technical regulations. Potential problems are identified at an early stage and can be rectified before they lead to a breakdown.

Predictive Maintenance

Predictive maintenance looks at asset condition and history to optimize the timing of maintenance. This leads to various savings:

- Minimization of maintenance time

- Minimization of production downtime due to maintenance work

- Optimization of the use of resources

- Reduction of costs for spare parts

- Increase of the plant availability

- Reduction of maintenance costs

Corrective Maintenance

Corrective maintenance begins immediately after a malfunction is detected in an asset. Within the framework of a regulated maintenance process, functionality is automatically restored as quickly as possible, taking into account the HSE criteria. Important attention is also paid to potential hazards and necessary precautionary measures. The respective work is then documented.

Prescriptive Maintenance

Prescriptive Maintenance is an approach to maintenance based on data-driven analytics and algorithms. By combining comprehensive asset data and innovative technologies such as machine learning, it generates precise recommendations for the optimal maintenance of assets. Furthermore, prescriptive maintenance not only provides information on when an asset fails, it even suggests steps on how to delay or completely avoid asset failures. The entire maintenance cycle is integrated and, for example, spare parts can be ordered and scheduled at an early stage.

Condition Monitoring

Condition monitoring is a method of continuously monitoring assets to detect potential problems at an early stage. It enables the condition of assets to be monitored in real time, faults to be detected immediately and corrective maintenance action to be taken directly. Warning monitoring enables maintenance activities to be planned before a warning ever becomes a fault.

Visual inspection extends the scope of condition monitoring through the use of external sensing, such as cameras, thermal imagers, or other observation techniques. The condition of the asset can be assessed by image recognition, pattern recognition or other algorithms to detect problems and trigger the follow-up actions in the EAM system.

Anomaly detection is an important extension of condition monitoring and uses e.g. machine learning algorithms to identify potential problems in a system at an early stage and trigger corrective action. Anomaly detection can be used in production to minimize downtime or production errors by detecting anomalies in real time and automatically triggering a corrective action.

Reliability Centered Maintenance (RCM)

Reliability Centered Maintenance (RCM) is a method for developing maintenance strategies based on asset reliability. RCM enables the identification of critical functions of assets and the development of appropriate maintenance strategies to focus on these functions in particular.

Mobile maintenance (Mobile EAM)

Mobile maintenance (Mobile EAM) simplifies and integrates daily operations for maintenance staff, provides all necessary data on-site and in the cloud, and alleviates cumbersome documentation procedures. The use of mobile technologies and devices allows access to important information, work instructions and schematics using mobile devices. In addition, updates are possible in real time. This eliminates the need for paper documentation and further drives automation.

Mobile EAM is an intuitive and powerful solution for increased efficiency in maintenance.

RODIAS Expert Tip: Our Solutions and Partners

Enterprise Asset Management mit IBM Maximo

IBM Maximo was developed as a platform specifically for the maintenance of complex plants, while other software in this area offers only limited possibilities as an add-on to ERP packages. In addition to the standard functionalities, additional functionalities such as condition-based maintenance, service desks or artificial intelligence for predictive plant optimization can be used at any time. All of these are already available in IBM Maximo or can be integrated at short notice.

- Reduce incidents and downtime risks to save costs and ensure smooth production flow.

- Automate asset management, including maintenance, to keep your assets up and running.

- Benefit from industry-specific best practice workflows to get off to the best possible start.

- Extend the lifecycles of your assets while improving their reliability.

Enterprise Asset Management with Hexagon (HxGN)

HxGN EAM helps business to digitize and evolve maintenance for highest efficiency. The leading solution is designed for perfect integration in industry-specific versions to meet individual requirements. Unlike limited niche solutions or extensions to ERP systems that require extensive customization, HxGN EAM excels in asset management through its tailored design that grows and transforms alongside your business.

- Unify your asset management processes to save costs and ensure a smooth production flow.

- Streamline workspaces, schedules and tools so employees can focus on other tasks.

- Improve maintenance operations by adopting and managing predictive maintenance concepts for machines.

Enterprise Asset Management:

Current examples of our customers

As a medium-sized IT consulting company, RODIAS has specialized in the implementation of systems for the management and maintenance of complex plants and buildings. In doing so, we prefer to use the provider IBM Maximo.

As the largest IBM partner in the Maximo area in German-speaking countries, RODIAS has specialized in systems for the management and maintenance of complex assets. You want to know how your company and its environment can concretely benefit from an Enterprise Asset Management of the latest generation?

Frequently asked questions

An enterprise asset management system is a software that manages fixed assets (buildings, machines, etc.) of companies and coordinates all related services and work. These can be e.g. maintenance and repair, but also cleaning, inspections, relocations or similar processes.

To support these processes, the most advanced technologies such as IoT, cloud-based services, mobile handhelds, data glasses, etc. can be used, which, coupled with the EAM system, provide overall transparency and improved quality in the maintenance of these objects.

The first goal is a high technical availability of all available assets. This is the result of an optimized maintenance strategy that additionally supports all peripheral aspects such as the procurement and stocking of spare parts, the necessary qualifications/training of employees, and many other aspects. Potential Maximo users want to optimize costs and ensure that their assets comply with the applicable technical requirements.

Many companies do not have a central IT solution that can handle the high complexity of this task. The resulting lack of transparency prevents this optimization.

Digital EAM technologies with continuous data analysis ensure maximum reliability, security and sustainability while reducing costs.

The classic conflict of goals between the highest possible resilience and low maintenance costs is a thing of the past when using cloud-based enterprise asset management.

The focus is on asset-intensive companies from the energy, utilities, industrial manufacturing, building services and transport/logistics sectors.

Three main types of software solutions lead the maintenance software market: Computerized Maintenance Management System (CMMS), Enterprise Asset Management (EAM) and Asset Performance Management (APM). Each of these software solutions provides deep, data-driven insights into your operational processes and helps you get the most out of your assets.

A CMMS enables management of assets, work orders, inventory, preventive maintenance, condition monitoring and more. It also acts as a central control system for maintenance and reliability strategies and provides a master database for capturing your maintenance information.

An EAM system helps you manage all of your company’s assets, your supply chain, spare parts inventories, financial systems and more.

APM software combines contemporary maintenance solutions with technologies such as sensors to optimize asset management. An APM system collects and processes condition monitoring data. This enables maintainers to take actions that minimize failures and unexpected downtime, thereby extending the life of assets.

Digital twins represent a kind of digital representation of real objects or systems. They can be used to replicate objects, products, services, but also processes, complete plants or factories in the virtual world. Digital Twins help you optimize processes: they typically support the understanding, prediction and optimization of the performance of a facility or operation. Their components are the data model, algorithms and expertise.

Mobile Enterprise Asset Management (Mobile EAM) refers to the mobile optimization of processes in the area of maintenance, operation and repair of tangible assets such as machinery, equipment, buildings and land, whether in companies or public institutions.

Software as a Service (SaaS) is a model for providing software from the cloud. Here, the cloud service provider develops and maintains the application software, provides automatic updates, and offers customers software access partly via the Internet.